Steel Connections

Wide Range of Steel Connections

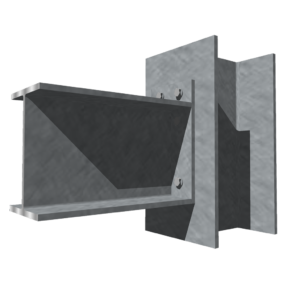

Angle Cleat

The main advantages of angle cleat connections are that no welding is required and that the bolt hole clearances allow minor adjustments to be made on site.

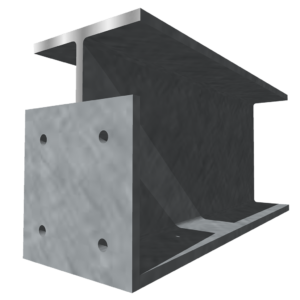

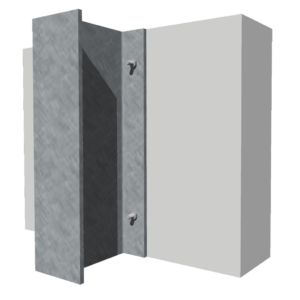

Back to Back Parallel

The 2 main types of Back to Back are Back to Back Channels and Beams. When a cavity wall needs to be supported above an opening, two PFCs can be bolted together back to back, with a spacer in-between, in order to give strength to the walls. The gap between the sections matches the width of the cavity.

Back to Back Beams are used when projects are struggling for height, for instance in basements and lofts, it is often preferable to replace a deep beam with two smaller beams. However, to ensure stability and resistance to buckling, these beams need to be bolted together. This is where a spacer is used and is usually welded to one of the beams.

Base Plate

Base plates are used as a support for columns coming off a concrete pad or foundation. To ensure longevity and stability, it is essential to leave a gap of around 20-30mm between the concrete and the steel plate, which can be achieved using shims and wedges. This gap will then need to be filled by packing a dry mixture of concrete (also known as a dry-pack) into the gap.

Beam and Bottom Plate

A bottom plate is added to a beam in order to support brickwork or timber joists. The bottom plate is stitch welded to the beam and is often offset to one side so that the brickwork is sufficiently supported.

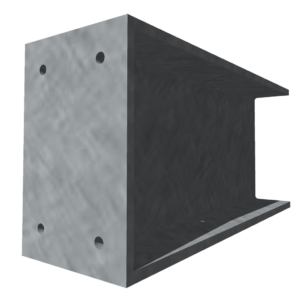

End Plate

An end plate is used to anchor the end of a beam to the wall, or is used to join a column to a beam or another beam to a flange. It is also part of the ‘End plate connection’.

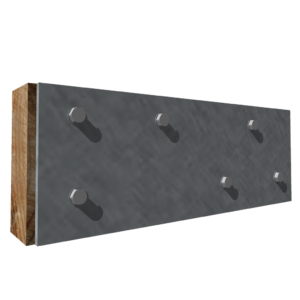

Flitch Plate

This is a steel plate that is drilled (generally in a staggered formation) to strengthen timber joists. Timber is usually bolted to either side of the flitch plate, which allows for the use of timber to span greater distances, where steel would normally be required.

90 Degree Crank Steel

A 90° crank is a typical crank but with two kinks. In a 90° crank the top member will be horizontal and the bottom vertical. Cranked beams are most frequently used to support roof structures, therefore the angle of the middle member needs to follow the pitch of the roof. It is crucial that full penetration welds are used with these connections to ensure the crank will carry the load.

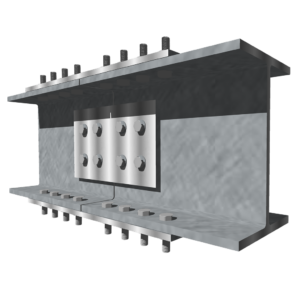

Splice

Splices are required when a beam is either too long or too heavy to install safely. When a beam spans two party walls, a splice is also recommended to easily install the beam, with the alternative being temporarily removing a large wall section. As a rule of thumb, the flange plates need to be at least the same thickness as the beam’s flange, and the same rule applies to the web plates.

In some cases HSFG (High Strength Friction Grip) bolts are required, in which case the beam ends and the splice plates must not be primed. These bolts are expensive, so if you are told they are necessary it might be a good idea to request a redesign by your Structural Engineer to enable you to use the normal 8.8 grade bolts.

The structural engineer may request additional inner flange plates for the splice connection.

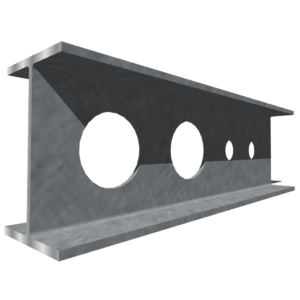

Holes in the Web

Holes are drilled in the web of the beam to enable timber joists to be fixed to both sides. Timber joist hangers are then fixed to the beam joists, allowing floor joists to be spanned from it.

Holes in the Flange

Holes are drilled in column flanges, either UC, UB or PFC, in order to anchor them to walls and as an alternative to welding tabs. In most cases M12 anchors are used every 600 mm and in a staggered formation.

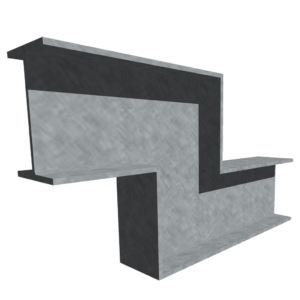

Dog Leg

A ‘Dogleg’ beam is a horizontal beam with a vertical section welded at 90°. This type of beam is often used to support existing staircases.